|

High-Speed Performance And Generous Work Area High-Speed Performance And Generous Work Area |

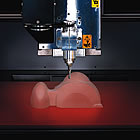

Featuring a powerful 100W brushless-motor spindle and 0.01mm/step software resolution, the MDX-40 quickly generates smooth-finished, beautiful results with precision every time. It accommodates a wide variety of low-priced materials including ABS, acrylic, chemical woods, plaster, styrene foam and wax. For optimum performance with a range of materials and cutters, the MDX-40 offers an adjustable spindle speed ranging from 4,500 to 15,000 rpm. Additionally, the MDX-40 features a generous work area of 305mm(X) x 305mm(Y) x 105mm(Z) (12"x 12"x 4.12", large enough for most small- to mid-size SRP applications.

|

|

Easy To Operate Easy To Operate |

| The MDX-40 is designed for easy operation with only four buttons: power, view, tool up and tool down. An on-screen operation panel makes using the MDX-40 even easier, allowing you to quickly select settings for both cutter movement and the cutting start location. Factory included origin sensors easily help identify the cutter tip and Z0 positions. |

|

Designing with MDX-40 Designing with MDX-40 |

|

Optional Rotary Axis Unit and Scanning Sensor Unit Optional Rotary Axis Unit and Scanning Sensor Unit |

The MDX-40's Rotary Axis Unit*1 is designed for unattended 3D milling at any angle from 0 to 360 degrees. With the Rotary Axis Unit, you can easily and accurately mill a wide variety of two- and four-sided objects. In addition, an optional scanning sensor unit*2 can be easily installed. This unit comes with Dr. PICZA 3, full-featured scanning software that includes a wide variety of editing functions. With Dr. PICZA 3, scanning data can be exported in DXF, IGES or VRML formats, or as Point Cloud data (ASCII).

*1 Work area is reduced with the Rotary Axis Unit

*2 The Scanning Sensor Unit cannot be used with the Rotary Axis Unit. |

|

|

| Rotary Axis Unit |

Scanning Sensor Unit |

|

Clean, Quiet and Safe Work Environment Clean, Quiet and Safe Work Environment |

| The MDX-40 features a compact footprint and fits easily on the desktop. A machine cover ensures a clean and quiet operation, making it ideal for office use. A new optional dust box collects cutting dust, further promoting a clean work area. An emergency stop switch ensures safe operation. |

| |

|