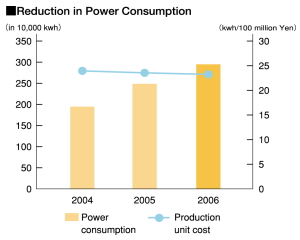

To reduce power consumption

company-wide, Roland installed "Eco-Ice" for

air-conditioning equipment in 1999 when the

factory expansion was completed. In

addition, a power control system was

installed in 2001 to reduce peak power

consumption and improve energy conservation.

To reduce departmental power consumption,

Roland personal computer monitors are turned

OFF when operators are away, CRT monitors

are replaced by LCD monitors,

air-conditioning temperature settings are

controlled in summer and winter, and

fluorescent lighting has been controlled and

replaced by energy-saving alternatives. As a

result, the 1% reduction target compared to

2005 was achieved in 2006 (on the basis of

production unit costs* 1 ).

Roland opened the Miyakoda factory in

December 2005, introducing a number of

energy-saving environmental design features.

To reduce the power consumption of

air-conditioning equipment, "Eco-Ice" (for

effective power usage after hours) was

installed, the number of heat-sensitive

windows was limited, and motion

sensor-controlled lamps were installed in

the corridors. |

| *1:

Production unit cost base:

Power (kwh) consumed per total production of 100,000,000 Yen |

|

Energy-Generating Programs

This program generates environmentally friendly,

clean energy from recyclable resources.

|

A. Additional Solar

Power Generation Facility Installed at

Headquarters |

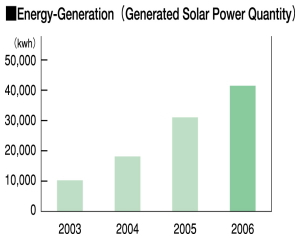

In

September 2003, Roland installed a solar

power generation system (11.25kw) through a

base/panel assembly process completed

entirely by employee volunteers. The

facility became operational on October 1st,

generating approximately 13,000 kwh for the

first year. Roland added similar systems in

October 2004, 2005 and 2006, which began

generating power on November 1st

respectively.

These facilities together have the capacity

to generate 45.0 kW and contribute 72% of

the lighting power consumed in 2006 for

production. In addition, these facilities

help reduce carbon dioxide emissions by

approximately 18 tons annually.

For 2007, we are planning to add a 9.00 kW

system (total 54.00 kW) by the end of

October and to start operating it from the

beginning of November.

|

|

|

|

Solar power generation

left panels added in 2006 |

Assembled by

employee volunteers |

B. Small Wind Power Generation

Facility Generating at Headquarters

On July 20,2004, Roland installed a small wind

power generation facility. The vertical windmill can

rotate to generate power whenever wind is present,

irrespective of its direction.

Power stored during the day and generated at night

is used for landscape lights. The facility is

located in front of the Headquarters on the left

hand side.

|

|

|

| Windmill |

|

Landscape lights (when lit) |

|

C. Small Hybrid LED Panel

Lamps generating at Miyakoda Factory

The company installed one small hybrid (wind +

solar) LED panel lamp and five solar LED panel lamps

on November 24, 2005. The energy-saving,

high-intensity LED used for each lamp illuminates

the parking lot at night. These lamps are located in

front of the Miyakoda factory on the right hand

side.

|

|

|

|

Full view of

hybrid panel lamps |

Panel lamps at night |

Solar LED

panel lamps |

|